Second Hand Tools

I am always looking for used wood turning or carving tools for myself and other turners, so if you have any I would love to have a look at them.

Tools used or created

Drill Chuck

See my chuck article in Woodturning Magazine

I made this simple device so that I can quickly mount

a keyless jacobs style chuck on my lathe without

having to remove the lathe chuck

It consists of an aluminium plate with a chucking

spigot machined on to one side, and a keyless

chuck attached with it's retaining screw

Grinder Carousel

See my article on how to make a grinder carousel in

Woodworking Pland and Projects

It doesn't really matter how big your workshop is, you never

have enough space

Here I have created a space saving way of mounting all your

grinders in a convenient and easy to use way

Just turn the carousel and you can get to whichever grinder

you need for a particular sharpening task

The old filing cabinet provide convenient storage at a good

height for me, and the castors provide essential mobility

Floor Vac

An essential tool in my workshop

An essential tool in my workshopA floor vac adapter for my chip extractor. This has been assembled

from some common ducting parts

Version 1 had the wheels inside the duct as I thought that it would be

easier get into tight spaces. However the internal wheels attracted

long shavings etc. and when they wore down I put the replacement

wheels on the outside

This has not impeded access to small spaces, but has resulted in

less shavings becoming entangled

In order to spread the load from the point of a revolving centre

so that it desn't bite into the wood too far I simply place a

heavy penny washer over the end. At first these were fiddly to

get in place until I started using a small piece of Blu-Tack.

This technique is particularly useful when turning end grain

Hollowing Rest

A friend asked me if I could make an extended rest for him

A friend asked me if I could make an extended rest for himto ease hollowing of deep vessels. I provided two versions

in one. One with bolts to constrain the movement of a gouge

and another with a platform for a scraper

and another with a platform for a scraperI must get around to making one of these for myself one day

Offset Turning Jig

Spiraling jig made from a readily available engineers Boring Head to

Spiraling jig made from a readily available engineers Boring Head toprovide the precise side to side movement with a custom made

24 position indexing plate on the front with multiple screw holes for

mounting the work

To use the device you slacken the locking locking screws at the back

of the aluminium plate and rotate it as desired. There is a ball bearing and

spring detent to provide the 24 position indexing and I engraved numbers

round the body to make selecting positions easier

Then if the design calls for it you can offset the whole front plate by winding

the Boring Head mechanism

You mustn't forget to lock it all again before turning the next element otherwise

you may loose registration and you will get the most horific juddering

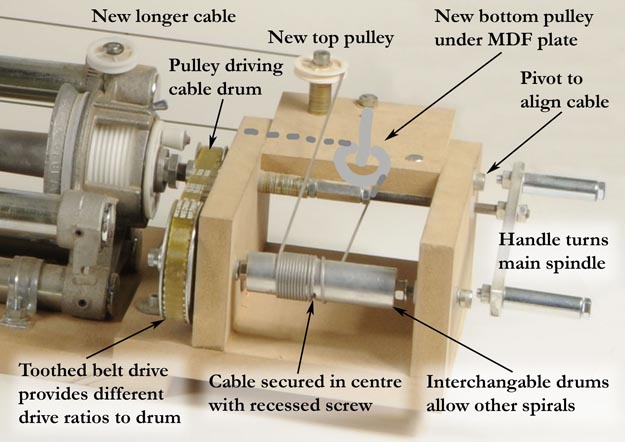

Router Lathe Modifications

Trend Routerlathe geared

Trend Routerlathe geared

with toothed pulleys, with

interchangable drums and

longer cable to allow greater

flexibility when cutting spirals

Tool Handles

System handles are expensive and often rely on grub

System handles are expensive and often rely on grub

screws which bite into tools

Aluminium tube, a 22mm compression joint and an

ER25 collet, together with a suitable covering provide

an inexpensive but flexible alternative.

I initially tried cricket bat grips, however whilst good

initially, they degraded very quickly, so I now use a

textured heat shrink tubing which is much more resiliant

Cork Faceplate

Cork Faceplate

A cork floor tile on MDF backing held in a chuck provides

a very secure and non-marking way of providing a friction

drive to clean up the bottom of a bowl